Hi-Vis is a form of Personal Protection Equipment (PPE) designed to make workers more visible to others in order to minimise the risk of injury.

The Australian legislation has Hi-Vis standards around the criteria, types and when it is to be worn.

Every construction site must have:

- Hi-Vis policy or rules

- Guide on how to wear and fit correctly

- Training on its effectiveness and better options for risk control.

As a business owner, you must manage the risks associated with your workplace activities and in doing so follow a process to control those risks. If you cannot eliminate a risk, you must implement measures to reduce the level of risk, provide training to workers, and provide PPE – which includes hi-vis.

Protective clothing is one of many control measures used to mitigate risk, however, it is the ‘last line of defense’, and all other reasonably practicable control measures should be in place first before relying on protective clothing. It is up to the PCBU if hi-vis clothing is a control that will be implemented on-site. However, it should always be worn around moving vehicles, plant and machinery.

Types of Hi-Vis

There are many types of hi-vis clothing available in Australia, and it is important to understand the different types of hi-vis, what is appropriate for your workplace, and ensure that you supply hi-vis that meets the standards. The two hi-vis colours that meet the standard for daytime visibility are yellow and orange.

- Class D – (Daytime use) made from fluorescent or other high visibility materials, are designed for daytime use. They are intended only for use in workplaces where lighting levels are good, and no work is done outside of daylight hours.

- Class N – (Nighttime use) designed and only suitable for night use, with no background material specified. The reflective tape must meet certain measurements and configurations.

- Class D/N – (Day and nighttime use) These garments combine fluorescent or other high-visibility background materials with strips of reflective tape, making them suitable for day and night use, or for work areas where there are low light levels.

Maintaining Hi-Vis

It is important that the correct hi-vis is selected and used correctly. Your workers should know:

- When using hi-vis is required

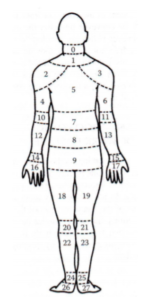

- How to wear it correctly, and that the zippers/velcro need to be done up securely

- Be of a suitable fit and not interfere with normal movement

- Be compatible with any other PPE requirements

- Know when to request a replacement due to damage/wear and tear

Hi-vis should be maintained to ensure that it remains effective, over time the materials can fade which will affect the performance of the tape and fabric. It should be regularly checked for wear and tear, fading, and ensure that there are no additional fabrics, logos, or pockets impacting the functionality of the hi-vis in accordance with the standards AS/NZS 4602 and AS/NZS 1906.4.