Get your team involved in health and safety, and watch your workplace become a safer, happier place for everyone.

Under health and safety legislation, businesses have a duty to engage with workers and enable them to participate in improving health and safety. The business must:

Remember that your subbies are also considered your workers when they are working for you.

Together with your workers, you can determine the best way to meet these requirements. What is reasonable and practicable will depend on your workers’ views and needs, the size of your business, and the nature of its risks.

Businesses must:

You will need to engage and consult with workers who are directly affected by a matter relating to health and safety. This includes when:

It’s important to have meaningful and effective health and safety talks. It’s good for people and for business. This doesn’t mean hour-long talks or lots of documentation, it’s simply about approaching H&S with the right attitude and aiming to get everyone involved.

HazardCo makes it even simpler to do this with our ‘Toolbox Meeting’ feature on our HazardCo App – handy for making sure everyone on-site is keeping on top of what’s going on.

If you need a hand getting started or would like more information, get in touch with the friendly HazardCo team today.

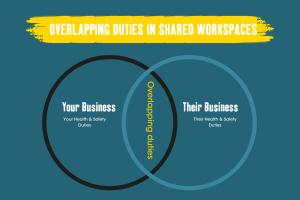

In the world of construction, it’s common for duties and health and safety responsibilities to overlap. This can be managed simply – just follow the three C’s – Consultation, Cooperation, and Coordination and you’re on your way to a safer work site!

Basically, an Employer is required to ensure the health and safety of their workers, contractors or any visitors who might be affected by work operations.

On-site this means that there can be a lot of overlapping duties, so the principal contractor is responsible for coordinating with other businesses/trades/subcontractors so they can all meet their combined responsibilities. See the image below:

When there are multiple businesses at the same site, each business must do what they can, within their control, to keep workers safe. In these situations, the most effective way to manage workplace health and safety is by working together.

By following the three C’s everyone will be aware of their overlapping duties, so roles can be clearly defined and work isn’t impacted.

Consultation between businesses can help you all reach a common understanding and establish clear roles, responsibilities, and actions in relation to work health and safety. Consultation could require discussions around:

From the consultation comes cooperation. This simply means sharing information and working together to put in place systems for managing and controlling risk agreed during the consultation process. Working together can increase the scope of the hazards recognised – ultimately making the site safer!

And last but not least – now actually making sure everything works well together. Businesses should be able to coordinate on what systems will be implemented to control risks. This isn’t about one business pushing all the duties down on another, it’s about everyone involved working together to avoid duplication, or worse, health and safety risks.

What may seem like a hassle at first, is actually a huge benefit to life on-site. Keeping people safe should always be the top priority on any construction site – and of course, Health and safety laws actually require this to be the case. Aligning yourself with other Employers on site and knowing what safety systems are in place is vital and can save lives.

If you are a principal contractor you must document the arrangements in place for consultation, cooperation, and coordination between all the different Employers at your site in your Site Specific Safety Plan (SSSP). The HazardCo system will guide you through creating a SSSP for each of your sites – Test drive the SSSP generator.

Managing your contractors and their H&S responsibilities is easy with the HazardCo system. You’ll get all the tools you need to pre-qualify contractors and check their H&S systems are up to scratch, plus everyone will be able to use the guided HazardCo app on site to create SWMS, log toolbox meetings and more. Get a 7-day HazardCo trial.

If you are a contractor and you have questions on how to best work with other businesses or the process you should follow, have a look at our Overlapping Duties: Working with other businesses blog.

Each year more and more builders are using construction software to manage their business, both on site and in the office. Building companies with good systems and processes in place (particularly digital ones) can create strong, resilient businesses that are prepared for anything. If you’re scrambling around with paperwork and manual time-wasting tasks like it’s the year 2000 check out this guide on the latest in construction software. Go digital and build a resilient business that gets ahead in 2024.

Here are some of the most popular tools that will help you shift into the next gear:

Connected Supplier Network

BuiltGrid is the construction industry’s connected supplier network. The platform helps builders to engage with existing trades, services and material suppliers or find new ones.

With access to over 9800+ trades, services and suppliers BuiltGrid will make sure you can win your next project and complete it on time and under budget, profitably.

As the market continues to evolve it can become more difficult for builders to win the projects they want. Toby Loft, co-founder at BuiltGrid says, “Having great supplier relationships is important, but having access and visibility over the market rate is vital to winning the projects you want. BuiltGrid users are achieving cost reductions of over 9% in time, work and materials, these gains are helping them win the projects they want while significantly boosting profits.”

Construction management and estimating software

Buildxact is job estimating and job management software designed specifically for residential builders, renovators and trades. It’s the market-leading option for Aussie builders who want to run their construction project from takeoff to the final invoice, all-in-one place.

Buildxact continues to evolve and bring out new tools. It now integrates directly with your favourite suppliers to get the latest prices, which makes the quoting process quicker and more accurate. And a new mobile tool connects you with your on-site crew, to make sure you never miss a beat from the job site again.

Take advantage of estimating software uniquely designed for residential builders and trades. Check out the HazardCo and Buildxact New Year combo offer, running until the end of Feb 2024

Learn more about Buildxact.

Pre-account software

Dext Prepare is a game-changer for the construction industry, streamlining your financial paperwork management. The app automatically extracts, categorizes and stores all the information you need from your financial paperwork so you can easily submit to accounting software – anywhere and anytime.

Dext Prepare’s leading-edge accuracy and rapid processing remove the need for time-consuming manual data entry. This helps you save valuable hours each week and lowers the risk of errors in your books. This is critical in the construction industry, where financial clarity can impact project timelines and budget management.

Seamlessly integrating with all main accounting platforms – including Xero and QuickBooks Online, Dext Prepare ensures your financial records are always accurate. Your data is stored securely for ten years, providing a reliable archive for easy reference whenever necessary.

With Dext Prepare handling your expenses data, you can focus more on the operational aspects of your construction business, secure in the knowledge that your financial records are in order.

Learn more about Dext.

A simple health and safety system

HazardCo is a health and safety system that makes WHS simple, giving you the confidence you’re keeping your crew and business safe while cutting the time you spend on paperwork.

Paul Shelton from HazardCo says, “You can’t completely avoid the admin that comes with running safe sites but we can make it a heap easier by removing all the time-consuming parts. Lots of small builders will choose to digitize their H&S system before anything else, as it’s an easy win that’s quick to implement and has instant results. If you haven’t seen a demo of HazardCo recently it would be worth looking at it again as lots of new contractor management tools were added to the system last year.”

As the main contractor, you’re responsible for the WHS of everyone on site, not just your direct employees. HazardCo has new and improved tools to get your contractors involved in H&S. As well as saving time, automating your contractor management processes helps to deal with labour fluctuations and provides flexibility.

Find out more about HazardCo.

Property Information

Looking for an efficient way to search for potential sites and check feasibility? Conducting due diligence and reconnaissance from your laptop is really easy with Landchecker’s on-map functionality.

Quickly and easily searches properties to identify key insights, such as; heritage overlays, flood zones, bushfire-prone areas property boundaries, site dimensions, zoning maps, planning permit applications, topography, precinct structure plans, last sold price and more.

Access property titles and plans at competitive prices with one click purchase.

All paid plans now come with High-Resolution Aerial Imagery so you can analyse geospatial data for a “full-picture” view that reveals how potential development site locations/suburbs are

changing over time.

Client budget validator

ProCalc is a quick budget validator that draws data from thousands of residential builders’ projects over Australia.

Builders use ProCalc to accurately ballpark construction concepts in just 15 minutes from their desktop to eliminate tyre kickers & time wasters from their sales pipeline. Reduce wasted time on detailed quotes for clients who couldn’t afford the project by giving them a quick ballpark immediately before proceeding further to detailed estimates.

Builders also use it to stop under-quoting projects. If clients can’t afford their original design, easily ‘tweak’ ballpark estimates in minutes to reduce the scope so you can still win the job but protect your margins. When you’re ready, you can apply localised market construction rates to ballpark estimates to inform your final detailed estimate. Plus, builders can choose the architects/designers they’d rather work with as the preferred builder (rather than the price checker).

ProCalc was created by a builder after interviews with hundreds of registered building practitioners. ProCalc is the missing link in qualifying which prospects can afford your services – those worth investing your time in. Most builders using ProCalc say they save 2-4 days per month in estimating so they can focus on real prospects who become real, paying clients.

Accounting software

Xero is online accounting software for your building company which makes it super easy to automate your admin. Plus, you can work from anywhere, even your ute!

When it comes to construction accounting, if you don’t do it regularly it’s easy to fall behind and things can quickly get out of control. By building accounting into your regular workflows you’re always on top of it. Xero is cloud-based and simple to use. Whether you are on-site or in the office you can access Xero on your smartphone or tablet so you’ll never get behind.

Xero connects to your bank, bookkeeper, accountant and other financial apps you might use such as Dext.

Find out more about Xero.

Any work undertaken near live overhead electric lines carries the risk of electric shock. Touching a live overhead line with any part of the body, tools or any other equipment can cause serious injury and even fatality.

Make sure that you and your team are aware of the following steps that can be taken to manage the risk of an electric shock.

You must prepare a SWMS before work starts and make sure it includes all the potential hazards and expected controls. Collaborate with your workers in developing the SWMS, ensuring they understand how the task is to be performed.

The safest option to eliminate the risk of electric shock is to temporarily disconnect a property’s electricity supply from the electricity distribution lines so that the overhead line to the property is no longer live.

Find out who needs to know that the electricity supply will be temporarily disconnected. Such as:

Anyone who could be affected by the disconnection of the electricity supply should be told:

If work needs to take place near an overhead electric line then the worker’s body, their tools, and their equipment must be kept a safe distance away from the overhead line, or else the electrical supply must be disconnected by the approved electrical supplier. This is known as the safe approach distance, or SAD.

More information on Safe Approach Distances can be found on your state Regulator’s website or contacting the energy supplier.

Keeping you and your team safe at work is a priority, so make sure you are aware of the requirements of working near power lines. The HazardCo App Site Review resource has a list of electrical controls that should be in place to mitigate the risk of electrical hazards. If in doubt, you can give our team of Health and Safety Advisors a call on 1800 954 702.

Worksites tend to be filled with constant noise from tools and machinery.

While noise often means things are getting done, there is a downside to it. Hazardous noise can affect a worker’s physical and mental wellbeing including hearing loss, stress, and lower productivity. So to help you protect your hearing, here are a few helpful tips to keep your ears in tip-top-shape.

Understanding what makes noise on-site and how it impacts people and different areas on site is critical. Ask yourself and your workers:

Once you understand the answers to the above, you can start putting actions into place to control noise on-site.

Be sure to monitor and review the controls throughout the project, as different stages will create varying levels of noise.

The easiest way to decrease the effect of excessive noise on your site is to eliminate the source of noise completely. But, chances are this isn’t possible on a busy site.

The next best thing is to reduce noise.

A couple of easy ways to do this include:

Isolation involves creating a dedicated space for ‘noisy work’. This could be an enclosed room or area of site where all noisy work and machinery is used or placing workers in an enclosed cabin when operating mobile plant. This helps to block the path of noise and reduce the levels that reach your team.

Having a good understanding of how machinery and tools operate can help modify processes to reduce noise at the source. Engineering controls can include choosing attachments or parts that are noise reducing, or changing the way machinery and tools are used.

With noise comes vibrations. These vibrations can be just as harmful as the noise itself.

Here are a few strategies to help decrease vibrations when using machines or power tools:

It’s not possible to escape noise on-site, however we can put steps in place to help reduce the effect that noise has on us while we’re working.

It’s no secret being a tradie is a very physically and mentally demanding job, with long workdays and weeks placing the body under intense physical and mental strain.

Worker fatigue is one of the biggest hazards on-site. Fatigue can come in many different forms and be caused by a number of different factors. While fatigue may not be avoidable in today’s busy cycle, it is important we recognise the signs of fatigue and the steps we can take to reduce it.

Because at the end of the day, a tired worker is a dangerous worker.

When you are fatigued, you are less alert and aware of your environment; this can lead to an increased risk of errors, resulting in injuries or incidents on-site.

When working on-site, it is both the Employers and the Worker’s responsibility to recognise and reduce worker fatigue.

As an employer on-site you are required to provide a safe working environment, and that includes reducing fatigue. Here are a few strategies for ensuring everyone stays fresh:

Everyone is personally responsible for turning up every day in the best mental and physical conditions possible so that what you do on-site doesn’t affect the health and safety of others. Here are some tips:

Our bodies operate differently during the cooler and warmer months. During winter, fatigue levels tend to increase. With the colder temperatures, longer nights and reduced sunlight, our bodies naturally tend to shut down earlier in the day. During summer, we benefit a lot from longer days and more sunlight, however we need to consider fatigue due to hot weather and maintaining our hydration levels.

Fatigue is something that we all face in our busy work lives and it is often unavoidable.

However, it is critical we can recognise the signs of fatigue in ourselves or someone on-site and take the necessary steps to prevent fatigue-related problems from happening.

The moment we’ve all been waiting for has arrived—the Win a Holiday competition has been drawn!

Throughout October and November Mitre 10 customers had the chance to win a $2500 voucher by simply signing up as HazardCo members.

Our heartiest congratulations go to the lucky winner: Smart Built!

A big thank you to everyone who participated.

We have previously shared content on what to expect when your workplace is inspected by WorkSafe/SafeWork. Now – what happens in the event that your business has received a notice from the Health & Safety Regulator?

If the Inspector identifies an issue, the Inspector will discuss with you what needs to be done to address the matter. The three types of notices that could be issued are:

We’ve put together our top recommendations on what you can do after receiving one of the above notices.

Carefully read the notice and follow all the instructions listed on the notice. This is particularly crucial if it’s a prohibition notice, as it means certain work must be stopped immediately.

Make sure the site entry report and associated notice/s are provided to the Director/ Owner of the Business. We also recommend sharing the notice with other project sites /areas of the business so that they can assess their area to see if similar issues are present or where there is room for improvement. This is a great way to improve health and safety across all areas and sites of the business and to demonstrate Health and Safety is a top priority for all.

Bring the notice to the attention of all persons whose work is affected by the notice (e.g. conduct a toolbox talk and record it in the HazardCo app). Discuss how the business will address the items and by when. We recommend you provide regular updates to the workers on this matter. If you have any Health and Safety Representative (HSRs) who represents workers whose work is affected by the notice, make sure a copy is provided to them.

Make sure a copy of the notice is put up and displayed in a prominent place at the workplace or near where the affected work is being performed (and we recommend you communicate to workers where this can be located).

Promptly discuss with relevant suitable persons who will be involved in addressing the notice (e.g. conduct a meeting with management, supervisors etc) and prepare an action plan to address all items that have been highlighted in the notice. Regularly track action items for timely closeout.

Ensure you document and record discussions, meetings, and agreed actions. Record and track health and safety actions by creating and assigning tasks on the HazardCo Hub or on the App.

Collate all the evidence that will demonstrate you have addressed all the items listed and provide it to the Inspector prior to the due date for their review.

Remember HazardCo is here to help. Give us a call on 1800 954 702 and speak to our Health and Safety Advisory team for further guidance.

Safe Work Method Statements (SWMS) are an important tool to use within the Construction Industry for High Risk Construction Work (HRCW). We’ve listed the common myths we hear across the industry to help you get a better understanding of what really matters when it comes to using a SWMS, and how you can make sure your SWMS is going to help keep you and your workers safe.

Myth – You need to include all the relevant Health and Safety Legislation, Standards and Codes of Practice/Compliance Codes on the SWMS

Fact – It isn’t a legal requirement to include all the relevant Health and Safety Legislation, Standards and Codes of Practice/Compliance Codes on the SWMS. Some companies, particularly larger ones, might ask their contractors to include this information. You might want to consider using a SWMS template.

Myth – A SWMS has to be on paper

Fact – The SWMS should be kept at the workplace where the work is being carried out. It can be in electronic format (such as a SWMS App) or in a paper format as long as it is readily available to workers involved in the work, and for the entire time they are doing the work.

Myth – You need to include a Risk Matrix and score the hazards and controls on the SWMS

Fact – It isn’t a legal requirement to include a Risk Matrix or score the hazards and controls on the SWMS, however some companies (particularly big ones) might ask their contractors to do this.

Myth – A SWMS doesn’t need to be kept after the HRCW has finished

Fact – In most cases, a SWMS doesn’t need to be kept after the HRCW has finished, however if you have a notifiable incident it’s likely you will need to keep a copy of the SWMS for two years after the incident date. Notifiable incidents are incidents where there is a serious injury or illness, or a dangerous incident and there are certain criteria which can help to identify these types of incidents. If you have a notifiable incident we recommend you check with your Regulator (e.g. WorkSafe, Safe Work) about your requirements or HazardCo members can reach out to our Health and Safety Advisory team for incident support and advice.

Myth – Once a SWMS is developed, you don’t need to review or change it

Fact – Not true! If the control measures don’t adequately control the risk, it needs to be reviewed and changed. This might happen when:

At any stage, if work is not being carried out in line with the SWMS make sure work stops immediately (or as soon as safe to do so) and only resumes after the SWMS has been reviewed.

Remember, if you’re using a SWMS template, it needs to be specific to the site and the HRCW being conducted. Find out if your SWMS templates are up to scratch.

Myth – A SWMS can only include content relevant to the HRCW

Fact – Only hazards and risks that are directly related to HRCW activities need be included in a SWMS. You can add non HRCW hazards and risks if it makes sense, but don’t overdo it. We suggest removing anything unrelated to the high risk construction work to keep it simple.

Myth – A SWMS is required for all high-risk work

Fact – A SWMS is only required for the following High Risk Construction Work (HRCW) :

You must complete a SWMS before undertaking any high-risk construction work, so we’ve made it as simple as possible. The HazardCo App includes 25 easy-to-edit SWMS templates as well as all the other health and safety tools you need to protect your crew and your business. Get a free trial.

A Health and safety policy outlines your commitment as a business to providing a safe and healthy workplace and preventing work-related injury and illness. It generally outlines, how the business will effectively manage health and safety. Some businesses will choose to have additional supporting policies on specific areas of health and safety such as mental health, injury management and alcohol and other drugs.

Health and safety procedures are how you will effectively manage health and safety.

Typically there are two types of procedures:

Regardless of what procedures you intend to have for your business, ensure you develop procedures in consultation with your workers.

Employers under Legislation have a primary duty of care to ensure that workers are safe from injury and risks to health and this includes:

Having clear policies and procedures in place across the business can play an important role in addressing the above items and is a great way to clearly document how health and safety will be effectively managed.

Businesses are often asked to provide their company-level Policy and Procedure (P&P) document (or manual) to clients or other Employers to demonstrate how they effectively manage health and safety. For example, a Principal Contractor (such as a building company) might ask a plumbing business to provide a copy of their P&P document before they begin working with them. Being able to showcase your commitment and standard of health and safety can help you to stand out against the competition.

To create a comprehensive policy and procedures document, you’ll need expertise in health and safety, including a deep understanding of relevant legislation and best practice. Seeking assistance from a qualified health and safety advisor is the best option.

Luckily, if you’re a HazardCo member, we’ve already created a combined company level policy and procedures document for you. It’s written by our team of health and safety experts, especially for Australian tradies and builders operating in the residential construction industry. If you’re already a member, you can download your company level policy and procedures document from the HazardCo Hub.

We recommend that you read through the P&P document (make sure it all makes sense – give us a bell if it doesn’t).

The next step is to communicate and consult! Get your team together and have a toolbox meeting to discuss the health and safety policies and procedures, and talk to your team about what changes may be needed within your business. This will assist with making sure that everyone is managing health and safety well.

It’s important workers receive adequate information, instruction and training to do their job safely and this extends to procedures so workers understand what procedures are in place and when and how to follow them.

Remember it’s important to regularly monitor and review your health and safety practices across the whole business including out on-site. This will help you to maintain a safe and healthy work environment for all and continually look for areas of improvement.