To put it simply, health and safety regulators (WorkSafe / SafeWork) work with you and your workers to keep you safe and healthy. Their main goal is to ensure that across Australia, businesses are safe and healthy environments. It’s important to know that not all visits are pre-arranged and inspectors are allowed to show up at any reasonable time, regardless of whether or not you’re there. So, what should you expect when they come a-knocking?

What does a site visit look like?

Typically a visit from WorkSafe/SafeWork follows the below process:

Step 1: Conversation

A friendly chat isn’t that scary, right? When the WorkSafe/SafeWork inspector first arrives, they’ll have a conversation. This discussion is a two-way street where they’ll be looking to learn about your business, what risks you’ve identified, the actions you’re completing to minimise them and answer any questions you may have. Ensure you use this opportunity to ask questions and seek clarification if anything doesn’t make sense.

Step 2: Observation

Following the chat, the inspector will usually take a walk around your worksite to have a look around. Sometimes its a general walk around, other times it may be focusing on a particular area or activity.

If the inspector sees anything concerning during the walkabout, they will discuss this with you further.

Step 3: Processes and Documentation

At this stage, the inspector might ask to see what kind of processes and safe practices you have. This could include anything from your risk assessments, worker’s licenses or training certificates, machine maintenance logs, to incident reports. The focus will be on whether your processes and records demonstrate good health and safety practices for your worksite, workers and business.

So what are inspectors allowed to do during the visit?

Inspectors have the right to:

- ask you, your employees or other people questions

- take photographs, recordings and measurements

- ask to see your documents, make copies or take the documents

- take items away with them for examination, testing or for use as evidence

What happens if an issue is found?

If the inspector does find an issue, you and the inspector will discuss what needs to be done to fix it. The three main outcomes issued by the inspector are an improvement notice, prohibition notice, or an infringement notice.

- Improvement notices – The most common type of notice which directs a person to address an identified health and safety risk in a specified time. The inspector will explain what was identified, how things need to change, and the timeframe in which it needs to be completed.

- Prohibition notices – Directs the business to stop doing a particular thing that involves a serious risk to health or safety. For example, stopping a specific activity or instructing you to stop using a dangerous piece of machinery. The notice will tell you what needs to be fixed.

- An infringement notice – This notice, or fine, is a penalty for breaking the law. Depending on your state or territory it can include an on-the-spot fine for breaching certain health and safety laws and may lead to prosecution.

Using HazardCo can cut the time you spend on health and safety admin in half and can guide you through what you need to do to keep your workers and your business safe.

Of course, if there are any questions or concerns, just call us at HazardCo for help on 1800 954 702.

Electricity is essential on construction sites, but if the risks are not managed properly, it can pose serious dangers to people and property. Proper controls must be in place wherever electricity is used to keep everyone safe.

Because we use electricity differently across a site there are different ways to help manage the risks.

Residual Current Devices (RCDs)

An RCD is an electrical safety device designed to immediately switch off the supply of electricity when electricity ‘leaking’ to earth is detected at harmful levels. RCDs offer high levels of personal protection from electric shock.

There are three types of RCD:

Fixed at the switchboard

- A switchboard RCD is the best option in most situations. It protects all the electrical wiring and appliances supplied from that circuit.

- An electrician must install a switchboard RCD.

Built into the powerpoint

- A socket-outlet RCD is built into a standard powerpoint to provide protection to equipment plugged into that powerpoint and, if required, downstream protection of other powerpoints.

- An electrician must install a socket-outlet RCD.

Portable

- A portable RCD can be moved from powerpoint to powerpoint as needed. There are a few different types of portable RCD:

- Some plug directly into a powerpoint. An appliance or extension lead then plugs into the portable RCD.

- Some are built into extension leads or individual appliance leads.

- Some are built into Portable socket-outlet assemblies (PSOAs).

- No electrician is needed – you can buy a portable RCD at a hardware shop or from an electrical equipment supplier, just make sure it is fit for purpose.

Testing

Keep you and your team safe while working around electricity by checking your RCD regularly. Across Australia, the testing frequency is based off the standard, AS/NZS 3012:2019 which sets the specific requirements for construction sites and states:

- Portable RCDs are to be push button tested daily before every use and an operating time test is to be performed by a competent person every 3 months.

- Fixed RCDs are to be push button tested 1 month and an operating time test is to be performed by a competent person every 12 months.

If an RCD is tested and found to be faulty it must be taken out of service immediately and replaced as soon as possible.

Leads and Cords

Leads and cords are easily damaged, particularly those connected to equipment that is often moved. To protect them:

- Use cable protectors, covers, non-conductive hooks, and ramps.

- Protect leads from sharp objects, footwear, doors, vehicles, liquids, grease, and heat.

- Arrange leads to prevent tripping hazards. Avoid running leads across aisles or passages.

- Elevate leads to keep them off the ground and ensure they are accessible without needing a ladder.

- Use insulated supports to relieve strain on plugs.

- Inspect leads for damage before use and have them tested and tagged regularly by a qualified person.

Testing and Tagging of leads and cords

Inspection, testing and tagging of electrical leads and cords on construction sites are required to be completed every 3 months* by a competent person.

Any lead or cord that is damaged or that fails testing is to be immediately taken out of use and removed offsite. If you cannot promptly remove it offsite, consider other means like attaching a durable out of service tag so as to warn workers not to use that piece of equipment.

Monitor and Review

When you complete your regular Site Reviews using the HazardCo App, make sure that you are checking RCD’s and all other electrical equipment are in good working condition and are regularly inspected and tested.

Further Information

If you have any questions in regards to this topic or need more support , reach out to HazardCo and speak to one of our expert Health and Safety Advisors. You can contact us on 1800 954 702.

*For Hire equipment, inspection is required prior to each hire and testing is carried out at least monthly. If hire equipment remains on the construction site then the frequency listed applies.

Health and safety is a core part of any business but incidents and injuries on the job can still happen. According to SafeWork Australia, in the construction industry alone there were 15,877 serious work-related injury claims between 2020 and 2021, and in the same period, there were 316 fatalities.

Construction and trades make up a fair portion of incidents and injuries at work. When you think about the cost of the time off, it adds up to a pretty staggered sum. As of 2020 the average compensation claim looks like:

- $24,628 in compensation paid

- 10 weeks of lost time per person

With numbers like this, we need to help you find a way to improve the health and safety culture so you can make sure it’s safe and profitable as well.

The signs of poor health and safety

If you’re concerned that your health and safety policies and procedures aren’t being followed or maybe not quite up to scratch, there are a number of things you can keep your eyes peeled for:

- Poor Incident Reporting

- Blame Culture

- Poor Communication

So, how do you get your crew on board?

When it comes down to it, creating a culture of site safety isn’t as easy as putting new procedures in place and calling it a job well done – it’s up to you to involve and motivate your crew to be proactive and take safety into their own hands. You need to make sure that your crew are on board and are taking the right steps to create a safety culture.

Some steps you can take include:

Communication

It seems like an obvious one but poor communication can really hinder your efforts to create a safety culture. Having regular honest and open communication with your crew about why you’re talking about all things safety is the best way to help them understand the importance.

The more transparent and clear you are, the more likely they will be to really take the new initiatives seriously. Make sure that your crew has easy access to your current health and safety guidelines so they can stay in the know about any changes.

Support your staff

Site safety isn’t just about incidents on your site, it’s also about being a supportive employer who ensures their people are feeling safe and secure when they come to work every day. Make sure that the physical health, mental health and even emotional health of your people is a factor for how you manage them. Those working in construction and trades like other sections of society are at risk of depression, stress, or anxiety as well.

If you are taking steps to improve your site safety culture, make sure you factor in both physical and mental health awareness in all that you do for your staff. By providing resources and establishing an environment where your crew feels respected and safe to open up and express themselves you’ll be able to create a support system where you can look after each other’s wellbeing and mental health.

Training

Ensuring that your crew are trained up on all the correct licenses, procedures and health and safety practices is a sure fire way to make sure that they are fully knowledgeable on correct procedures. With the right training in place, you can have confidence that they know how to safely and correctly perform their jobs.

Be a leader

We’ve all experienced bad leadership before, and that if they don’t care about something, it’s highly unlikely you will either. So, if your crew sees that you don’t take health and safety seriously, you’re out of luck getting them to foster a culture of site safety.

You need to walk the walk before you talk the talk. Demonstrate to your crew the importance of following health and safety standards by doing them yourself. They’re a whole lot more likely to follow your example than just take your word for it.

Reporting

You need to set the tone with your crew that reporting incidents isn’t something they need to feel anxious or uncomfortable about doing. Make it clear that they won’t get in any trouble for making a report but instead see it as a way of finding out what caused the accident or injury and what can be done to make sure it won’t happen again. By making proper reporting a core element of your crew’s job responsibilities it can become second nature to them.

Make it a team effort

Site safety impacts everyone, so it makes sense that your crew should have a hand in shaping their site’s culture. The more input they have, the more likely they are to follow precautions.

By having regular health and safety chats with your crew, you can give them the opportunity to voice their own safety concerns and opinions. By having open conversations and allowing input from your crew you’re giving them the ability to implement safety measures that affect their own jobs, ultimately making them more likely to follow processes and encourage others to do the same.

If you have any questions please reach out to the HazardCo team today

We’re going to run you through Respiratory Protective Equipment (RPE), which is a type of personal protective equipment (PPE) which protects people from inhaling substances that are hazardous to their health. These hazardous substances include airborne contaminants such as asbestos, hazardous chemicals and dust, fumes (such as welding fumes), and infectious substances, but you should keep in mind that RPE should also be worn to protect the wearer from low levels of oxygen such as working in confined spaces.

But, before you even get started with RPE, make sure you have other practical control measures in place such as local exhaust ventilation to minimise or eliminate contaminants in the air. Also, keep an eye on your team’s health and workplace conditions to ensure that they aren’t injured or made sick by their work.

We’ve gone ahead and put together a quick guide of factors to consider when providing your workers with RPE.

Types of RPE

Respirators that use filters remove contaminants from the air which the wearer will be breathing. Disposable respirators (often called dust masks) are good for short-term or one-off use and protect the wearer from harmful particles such as dust, fumes, fibres, and biological hazards such as bacteria or viruses.

Powered air purifying respirators (PAPRs) consist of headgear and fan assembly that take contaminated air, filters and removes a sufficient portion of these hazards, and then delivers the clean air to the user. These are also known as positive pressure masks, blower units, or blowers.

Supplied air respirators provide a supply of clean air to the wearer from a source such as an air compressor or cylinder. It’s important to note that the air supply needs to be checked regularly to make sure that it is safe to use.

Using RPE

It’s important for your workers to visually check their RPE for signs of damage before each use so that they can let you know if there are any issues, including whether it needs to be cleaned or decontaminated.

Make sure your team stays safe by keeping their RPE on while working in the hazardous area. Removing it for even a short period of time could be a risk to their health.

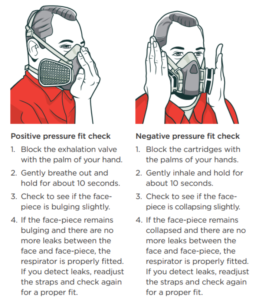

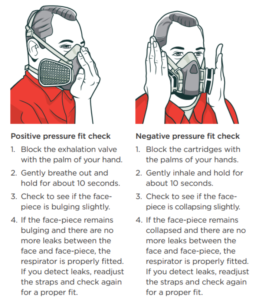

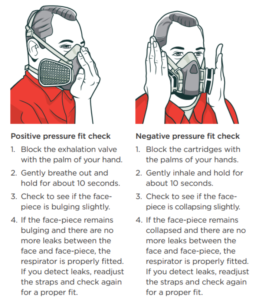

If your workers are using RPE that requires a tight fit, make sure that they are checking it properly before entering the hazardous area. There are two fit checks which they need to do:

Keep in mind that if your worker’s safety glasses fog up while they are wearing a half-face respirator, this is a sign that there is a leak at the top of the respirator.

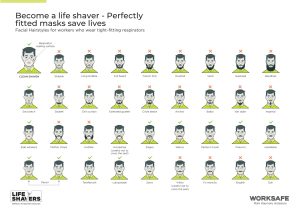

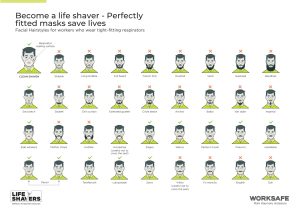

Life Shavers: shaving your beard could save your life

When your workers are wearing respiratory protective equipment at work, they should be clean shaven to ensure it is forming a seal and protecting them from breathing in hazardous materials. Even a small amount of stubble can prevent RPE from sealing correctly which means your workers will still be inhaling harmful materials which may cause health concerns. A clean shave goes hand in hand with the correct RPE for the job.

It’s your responsibility to monitor your workers’ health. Make sure that you are completing regular Site Reviews on the HazardCo App, as this will help you to identify potential hazards and put effective plans in place.

You’re probably across the recent engineered stone ban, but did you know SafeWork Australia has just come out with new rules to further protect workers from crystalline silica found in other building materials? These new rules begin on 1st September this year and apply to all states except Victoria whose rules are already in place.

Crystalline Silica Substances (CSS) include stuff like sand, stone, concrete, and mortar that contain at least 1% crystalline silica. When you cut, crush, drill, polish, saw or grind these materials, they release tiny dust particles called respirable crystalline silica (RCS). These particles are so small they can get deep into your lungs, which can lead to serious health issues, like silicosis—a lung disease.

What you need to do:

Risk Assessment

If silica dust is generated, assess if the work is high-risk. Document this using the handy Form in the HazardCo Hub, and if you determine the work is not high risk, you must explain why. If you’re unsure, assume it is high-risk. When assessing if processing CSS is high risk, consider these factors:

-

- The process

- Type and amount of silica (you can find this on the safety data sheet or product information sheet)

- Exposure duration

- If the work exceeds half the exposure standard (likely examples include grinding concrete, cutting concrete or bricks, jackhammering concrete or sandstone, and tuck-point grinding)

- Previous monitoring results

- Any past incidents or health issues related to silica dust

Put control measures in place (this applies to both low risk and high risk work)

Eliminate or minimise the risks from processing the CSS as much as possible and use at least one of the following measures during the processing:

- Isolate workers from dust exposure

- A fully enclosed operator cabin fitted with a high efficiency air filtration system

- An effective wet dust suppression method

- An effective on-tool extraction system

- An effective local exhaust ventilation system

If workers are still at risk of being exposed to silica dust after you’ve put one or more of the above controls in place they need to be provided with respiratory protective equipment (RPE) and wear the respiratory protective equipment while the work is carried out.

If you think it’s high-risk work:

Silica risk control plan

Avoid high-risk tasks when possible. If unavoidable, create a silica risk control plan outlining tasks, risks, and controls. This plan must be developed with workers, shared with them before starting work, and regularly reviewed for effectiveness.

What needs to be in a silica risk control plan?

- The processes you are doing that are high risk

- A copy of the information used to assess the risk

- What control measures will be used to control the risks and how those measures will be implemented, monitored and reviewed

Keep it simple and easy to understand—no need for lengthy explanations.

We suggest using the SWMS tool in the HazardCo App if the processing creates a contaminated atmosphere or involves high-risk construction work. Just ensure all the Silica Control Plan requirements are covered.

Training

Ensure that any worker involved in or at risk of RCS exposure due to high-risk CSS processing receives crystalline silica training. This training must be nationally accredited or approved by the WHS regulator and should cover health risks and the correct use of control measures.

Air monitoring

Conduct air monitoring if you’re unsure whether silica levels exceed the Workplace Exposure Standard (WES) or need to assess if there are health risks from RCS processes. Hire a certified expert like an occupational hygienist, to perform the monitoring and ensure it meets standards. If levels exceed limits, report it to the Regulator within 14 days. Keep records for 30 years and make them available to affected workers.

Health monitoring

Provide health monitoring for workers at significant risk from ongoing silica exposure, including those near high-risk processing. Keep records for 30 years and give a copy to the worker.

Review controls

Regularly review safety measures, especially after workplace changes.

If you need guidance, reach out to our advisory team at 1800 954 702 for assistance.

HazardCo understands that on-site first aid is about more than just sending someone on a course every few years. As an employer or principal contractor on-site, you have a legal and moral obligation to make sure your team has access to first aid equipment and facilities, as well as access to trained first aiders.

To determine the necessary level for your workplace, assess the site by considering:

- The type of work being done

- Identified hazards

- Site size and location

- Number of people on-site and any vulnerable workers

- Conduct a first aid risk assessment to identify facilities, equipment, and training..

Don’t forget to involve your workers in the process and if you are working with multiple trades, or are the principal contractor, you should share information and work together cooperatively.

First Aid Kits

Having a first aid kit on a construction site is essential to quickly address injuries and medical emergencies. Great kits can be sourced from many places – a basic kit should include equipment t to tend to:

- cuts, scratches, punctures, grazes, and splinters

- soft tissue sprains and strains

- minor burns

- broken bones

- eye injuries

- shock

Basic first aid kits are not always enough given the nature of construction work and increased risk of eye injury, cuts, falls etc, so you’ll need to consider what other equipment to add e.g. eye pads, eyewash, additional dressings and bandages.

Include your team and see if they think your first aid kit is sufficient for the site hazards and team size… and make sure they know who the trained first aider is and where the first aid kit is kept! It helps if your first aid kit is clearly labeled and is made from a material that can protect the contents from dust, moisture and contamination.

Lastly, assign someone to be in charge of replenishing the kit. Make sure this happens regularly and keep a list of what’s supposed to be in the kit to make topping it up easier. At the same time, check training is up to date for your first aiders, and if your team size has changed, whether you still have enough team members trained in first aid.

Keeping first aid up to date is the right thing to do by your team, so make sure you’ve got things covered and that you’re all prepared if any sort of injury takes place.

If you have any questions please contact the HazardCo team today.

It’s important for young people starting out in construction to understand how to stay safe at work. Young workers lack experience and might not know about all the hazards yet, which could put them in danger of getting hurt. Sometimes young people might feel like they have to impress others, or they might think they’re better at the job than they actually are, they may also forget about safety rules or be afraid to speak up if something seems unsafe. Because of this young workers have additional needs and should be supervised when working on-site.

Positive safety culture onsite comes from the top down, supervisors should be actively modeling and training young workers about safety rules, make sure they have the right gear, and encourage them to speak up if they see any problems.

There are some jobs that young workers shouldn’t do because they might not have enough experience or strength yet. Supervisors need to make sure young workers can handle their tasks and keep an eye on them until they are sure they are able to do the work safely. Young workers also need to think about their own safety, listen to instructions and follow safety rules.

When everyone works together to stay safe, it helps make sure everyone goes home safely at the end of the day.

Now, let’s delve deeper into some specific measures that can be taken to ensure the safety and well-being of young workers in the construction industry:

- Comprehensive training: Employers should provide thorough training. This training should cover specific job duties and safety procedures, hazard identification and emergency protocols. By giving young workers the necessary knowledge and skills, employers can empower them to work safely and confidently. Basic health and safety should be incorporated into their training from the start, and ongoing support should be provided to address any gaps in understanding. Regular check-ins to gauge their comprehension and comfort with procedures and equipment are essential.

- Clear communication: Good communication is key to creating a safe work environment. Employers should clearly communicate safety expectations and procedures to young workers, making sure that they understand their responsibilities and know how to respond in different situations. Young people often have fresh perspectives and questions that can lead to improvements. Encouraging them to voice their ideas can contribute significantly to a safer workplace for everyone.

- Supervision and mentorship: Experienced workers can play a vital role in guiding and mentoring on construction sites. Assigning a mentor or supervisor to oversee the work of young workers can help prevent incidents and ensure that tasks are completed safely and correctly. This also provides young workers with an opportunity to learn from experienced builders and develop their skills over time.

- Lead by example. Supervisors play a critical role in ensuring workplace safety. They should actively monitor work practices, correct unsafe behaviors, and be available to answer questions. Providing ongoing support and guidance to supervisors, especially if they are also young workers, is essential for maintaining a positive safety culture.

- Regular safety inspections: Regular inspections of the work site should be conducted to identify and address any safety hazards or potential risks. Employers should involve young workers in these inspections, encouraging them to participate in hazard identification and risk assessment. By regularly assessing and addressing safety concerns, employers can create a safer work environment for all employees.

- Ongoing education and support: Safety education should be an ongoing process for young workers in the construction industry. Employers should provide regular opportunities for training and development, keeping young workers informed about new safety regulations, procedures, and best practices. Additionally, employers should offer support and guidance to young workers as they navigate their roles and responsibilities in the workplace.

- Create a positive culture: Creating a positive safety environment involves more than just having policies in place. Supervisors should consistently reinforce safety practices and lead by example by wearing personal protective equipment. Implementing a buddy system can also provide additional support to young workers, allowing them to learn from experienced colleagues while fostering a sense of teamwork and collaboration.

Employing young workers in the construction industry has benefits for the young person, the company and for the industry as a whole as the next generation of builders learn and grow into future roles. By prioritising safety and investing in the well-being of young workers, employers can create a culture of safety that benefits everyone involved. Together, we can build a safer and more secure future for the next generation of construction workers.

If you have any questions, get in touch with the HazardCo team today

Tools, vehicles, and heavy equipment all create vibrations that can affect your body. This is a normal part of any tradie’s day, whether you’re picking up power tools or jumping in the ute. It’s so common that many don’t realise the potential harm these vibrations can cause. However, it’s something you should start thinking about and being aware of.

How are workers harmed?

Vibrations are a natural part of working on any construction site but they do create a risk to you and your workers. Repeatedly using vibrating hand and power tools, or being around vibrating vehicles and machines can lead to serious and lasting harm to your blood vessels, nerves, and joints. Many of the most commonly used items give off some form of vibration. Here are the most common ways tradies are exposed to vibrations:

- Power tools

- Vehicles and machinery

- From our working surfaces being exposed to vibrations (including break or smoko areas)

While these are the most common forms of exposure, the below should also be considered as they increase the risk of overexposure to vibrations:

- Working in cold and damp conditions

- Increased grip force

- Working with power tools for extended periods

Early warning signs

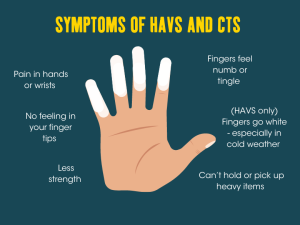

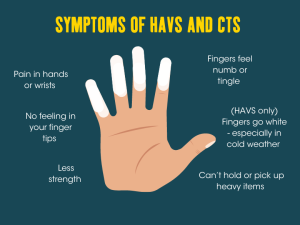

We understand that for many tradies, working with vibrations is a natural and unavoidable part of the job. With that in mind, there are a few warning signs and symptoms of overexposure to keep an eye out for:

- Tingling and numbness in your fingers (which can lead to disruptions to your sleep patterns – not ideal!)

- Loss of feeling in your fingers

- Loss of strength, both grip and holding, in your hands

- Fingers turning white and red when working in cold/ wet conditions

If you are continually exposed to vibrations especially in your hands and arms you can develop hand-arm vibration syndrome (HAVS) or carpal tunnel syndrome (CTS).

What you can do to manage risk

It is up to everyone on-site to look out for each other. Consultation with your team should take place to make sure an environment can be created where excessive exposure to vibrations are eliminated or minimised.

Below are simple yet effective ways to either eliminate or minimise the effects.

- Use suitable low vibration power tools where possible

- Use the right tool for the job – don’t use a power tool to get the job done faster when it is not required. Enjoy the task, don’t rush

- Look after your tools, vehicles and machinery – get them serviced regularly, repair any breaks or faults as soon as possible and store them properly – keep them out of the cold and rain

- Avoid gripping or being too forceful with a tool

- Keep your body moving and take a break if needed

- Wear the correct equipment and clothing

Above all else, be aware that vibrations can be extremely harmful, especially when you’re exposed for lengthy periods of time.

Your best tool for minimising the effects of vibrations is to start a conversation with your boss, or your team, and put steps in place to look out for each other and your equipment.

If you have any questions please reach out the the HazardCo team

Engineered stone ban summary

Updated on 26 August 2024

On 1st July 2024 an engineered stone ban will take effect in all states and territories. The ban prohibits the use, supply, manufacture, processing or installation of engineered stone benchtops, slabs or panels.

Further information is yet to come on:

- Notifying the regulator when you’re working with already installed engineered stone products.

- A stricter exemption process for engineered stone products to be excluded from the ban if there is strong evidence they can be used safely in exceptional cases.

New crystalline silica regulations

Until now, the focus has been on engineered stone, however crystalline silica can be found in many other building materials. It has just been announced from 1st September 2024 changes to the crystalline silica regulations will be made to further protect workers.

This includes working out if the processing of the crystalline silica substance is high risk and putting in place additional control measures if it is. Read our summary of the Crystalline Silica rules.

A new Code of Practice will be released in all states to reflect these changes. During its development, Safe Work Australia will provide guidance to help businesses and workers understand and comply with the new regulations.

Engineered stone FAQ

What is engineered stone?

Engineered stone is an artificial product that:

- Contains 1 per cent or more crystalline silica, determined as a weight/weight (w/w) concentration; and

- Is created by combining natural stone materials with other chemical constituents such as water, resins or pigments; and

- Becomes hardened.

What’s not included under the definition of “Engineered stone”?

- Concrete and cement products

- Bricks, pavers, and other similar blocks

- Ceramic wall and floor tiles

- Sintered stone

- Porcelain products

- Roof tiles

- Grout, mortar, and render, and

- Plasterboard.

Is there a transitional period?

- ACT, QLD and VIC – No transitional period.

- NSW, SA, WA, NT and TAS – Transitional period until 31st December 2024.

- If a contract was entered before 31st December 2023, the work is exempt from the engineered stone prohibition as long as the work is completed by 31st December 2024.

What about already installed engineered stone?

If you need to repair, remove, dispose of or make any minor modifications after 1st July 2024, you will need to notify your state regulator first. Notification forms will be available from your state regulator along with any other specific information such as timeframes and re-notification requirements.

VIC – A licence is no longer needed to work with engineered stone from 1st July 2024 and no notification will be required to work with already installed stone.

NSW, SA, WA, TAS, QLD – Notification forms will be available from your state regulator before 1st July 2024 and you will need to submit the form before starting any work.

NT – Written notification will be required every 12 months. The form will be ready before 1st July 2024.

ACT – Notification is required from 1st November 2024 and you will only need to notify once.

Remember, before starting any of the work you must have control measures in place to minimise the dust and you must wear respiratory protection.

Creating a SWMS in the HazardCo App can help you with selecting the right controls for the task such as using water suppression or on-tool dust extraction, and a minimum P2 dust mask or respirator.

Are there any alternatives out there?

There are plenty of silica-free options out there to suit every budget such as timber, stainless steel, and laminate options have come a long way, such as these Contact Sheet options from Laminex.

Resource links

https://www.safeworkaustralia.gov.au/esban

https://www.safeworkaustralia.gov.au/esban/faq

https://www.worksafe.vic.gov.au/frequently-asked-questions-engineered-stone-ban

Work Health and Safety and Workers’ Compensation Ministers’ Meeting – 10 May 2024 – Department of Employment and Workplace Relations, Australian Government (dewr.gov.au)

Information correct as of: 24th June 2024

Respiratory Protective Equipment (RPE) is essential gear for protecting you from inhaling hazardous substances. In this blog, we’ll explore the important role of RPE, whether you are dealing with airborne contaminants like asbestos, fumes, dust, or working in a confined space, RPE is an essential personal protective equipment (PPE) that makes sure you can breathe safely. Join us as we deep dive into the different types of RPE, their applications, and how they can protect you from potential health risks.

Before you even get started with RPE, make sure you have other practical control measures in place first; such as local exhaust ventilation or direct dust-extracted tools with a vacuum catchment to get rid of the majority of contaminants in the air. You should also be keeping an eye on your team’s health and workplace conditions to ensure that, over time, they aren’t being made sick or getting injured by their work.

Remember, there is no such thing as a healthy dust, even if you are outside!

We’ve gone ahead and put together a quick guide of factors to consider when providing your workers with RPE.

Types of RPE

Disposable respirators are good for short term or one-off use and when you have existing controls in place to give you extra protection. When using a disposable respirator you need to make sure a seal has been created to protect you from harmful particles such as dust, fumes and fibres.

Respirators use replaceable filters to remove contaminants to clean the air for the wearer. They come in half-face and full-face versions. The cartridge filters are specific to certain types of contaminants, ask your manufacturer exactly which cartridge you should be using for the respirator you have and the contaminants you will be facing.

Remember if you have stubble or any facial hair you may not be getting the seal and the protection you think you are! So if you love your bread as much as your lungs read on to find out what you can do

Powered air purifying respirators (PAPRs) consist of headgear and fan assembly that take contaminated air, filters it, and then delivers the clean air to the user. These are also known as positive pressure systems. These not only keep you nice and cool, but offer the highest protection there is for people who have facial hair. Something to note with these is that the visors and headset can be impact rated if you need it, and don’t fog up because of the airflow.

Supplied air respirators provide a supply of clean air to the wearer from a source such as an air compressor or cylinder. It’s important to note that the air supply needs to be checked regularly to make sure that it is safe to use – just think about what you see coming out of your air compressor when you release the valve under the air tank! The user must also be trained in how to use the system.

Using RPE

It’s important for your workers to be trained in using and maintaining their RPE. They should visually check their RPE for signs of damage before each use to identify any issues, including whether it needs to be cleaned or decontaminated.

Make sure your team keep their RPE on while working in the hazardous area. Removing it for even a short period of time is a risk to their health.

Did you know that they come in different sizes? One size does not fit all!

If your workers are using RPE then make sure they are fit tested, this way you will know who needs what size, otherwise it may not work and give the protection your workers need.

The manufacturer of the RPE can tell you who can do this testing.

There are two checks which you need to do each time you use and RPE:

1 – check for damage visually to the sealing surfaces and straps

2 – check the valves are functioning correctly like WorkSafe images below

Image Source: Worksafe New Zealand

Keep in mind that if your worker’s safety glasses fog up while they are wearing a half-face respirator, this is a sign that there is a leak at the top of the respirator which means they are not getting full protection.

Life Shavers: Shaving your beard could save your life

When your workers are wearing respiratory protective equipment at work, they must be clean shaven to ensure it is forming a seal and protecting them from breathing in hazardous materials. Even a small amount of stubble can prevent RPE from sealing correctly which means your workers will still be inhaling harmful materials which may cause health concerns. A clean shave goes hand in hand with the correct RPE for the job.

It’s your legal responsibility to monitor your workers’ health. Make sure that you are completing regular Site Reviews on the HazardCo App, as this will help you to identify potential hazards and put effective plans in place. Your HazardCo Advisory Team is available throughout the day to guide you through this – call 1800 954 702 to talk it over.

Image source WorkSafe

Looking for something in particular?

Kick off the New Year safely on site

The holidays are done and dusted, and it’s time to ease back into work. Reopening your site safely is just as important as shutting it down properly and t...

The Christmas break is nearly here. You're probably counting down the days until you can relax and spend some proper time with the family and friends.

But before you lock up for the holiday...

We’ve heard all sorts of myths and misconceptions when it comes to health and safety. We’re here to debunk some of the more common ones we hear.

H&S admin takes too long on-site...

Got lone workers on your team? Here’s what you need to know

If someone on your team is working by themselves without other people around and without direct supervision, they’re likely conside...

Take the Hassle Out of Toolbox Meetings.

Toolbox meetings don’t need to be a paperwork mission. With the HazardCo App, you can run quick, focused chats straight from your phone. No prep, no p...

Get your team scanning in and out – it’s a no-brainer!

We get it, health and safety chats aren’t always the most exciting. But they are the most important. When everyone on-site takes part,...

Working with heavy machinery and managing traffic on-site can be risky. But with the right checks and planning, we can keep everyone safe.

Daily machinery checks

Before starting work each da...

Digging into the ground might seem straightforward, but excavation work is actually one of the most dangerous parts of construction. That’s why it’s important to plan ahead and put the right s...

When you're able to get back on site after a flood or storm, here are the hazards, risks and control measures you should consider to help reduce the risk of injury and illness to yourself, you...

Dust is a common hazard in the construction industry, especially during demolition or refurbishment. When buildings are demolished they can release materials that create hazardous dust (airbor...

To put it simply, health and safety regulators (WorkSafe / SafeWork) work with you and your workers to keep you safe and healthy. Their main goal is to ensure that across Australia, businesses...

Electricity is essential on construction sites, but if the risks are not managed properly, it can pose serious dangers to people and property. Proper controls must be in place wherever electri...