Musculoskeletal disorders (MSDs) are the most common workplace injury and cause of lost time at work, so spending time to focus on it makes good business sense.

Research has shown that the old approach of teaching a person how to lift correctly has not been effective in reducing these problems. Many workplaces pay to bring various experts into the workplace to help them address Musculoskeletal disorders but a lot can be done inhouse by those leading the business.

1. Survey your workers for discomfort pain and injury using a body map:

To start a discussion around MSDs print and hang a poster of a body on a whiteboard or wall (see body map at the end of this article). Next to the poster, provide a marker or stickers for the workers to use to place crosses on the body parts where they have experienced pain or other MSD symptoms in the past week or month. Each worker can also make a mark at the bottom of the poster to indicate that they have contributed. When there is the same number of marks at the bottom as the number of workers, or it’s been established that everyone who wants to contribute has done so, the patterns that emerge from the poster can be used for a toolbox discussion and brainstorming session.

2. Ask your workers to take photos of things they think contribute to discomfort, pain, and injury at work:

Ask workers to take photos using their mobile phones over a two-week period. Each person (workers and managers) should take two or three photos of something that they perceive as risky or that they find triggers MSD symptoms at work. They can also take pictures of work situations or equipment that they perceive as helping to prevent MSDs. The quality of the photos doesn’t matter and they don’t have to be self-explanatory. Ask each worker or manager to provide brief explanations of their photos. To give an example of a photo of a risk, it might show the height of a ladder on a vans roof rack (which requires force and an awkward body position for workers to reach). An example of a picture of something that helps to prevent MSDs might be a photo of colleagues helping each other during a pressured time. Each person can be helped to print out their photos and stick them to a board (e.g. in a lunchroom or meeting room). Once the photo shoot is over, arrange a toolbox talk at which all the photos are on display and the topics raised can be discussed. The aim is to establish a shared understanding of what the photos represent.

3. Think about the physical and mental demands on your workers

There are well known physical and mental demands of work that lead to MSDs and lower productivity. Identify if you have any of these issues in your business:

Aim to address these demands by:

4. Where possible get work up off the ground:

Working and handling at ground level places strain on our bodies which overtime can develop into MSDs. Take photos of tasks that require stooping and bending to complete at your workplace. Look for items that are stored on the ground. During toolbox talks discuss ways which the task can be redesigned by raising the work off the ground for example with a trestle, pallets or providing a table. If it can’t be raised, can we extend our tools or modify our position to compensate?

5. Where possible eliminate overhead work:

Jobs that require overhead work are 2 to 3 times more likely to result in a shoulder injury. Overhead work becomes more hazardous when the arms are elevated over 60 degrees. Use a toolbox talk and photos to identify where overhead work is required. Where possible aim to eliminate it and where it must remain look to design alternative ways to complete it. This includes reducing the force required, using lighter and smaller tools, keeping the arm below 60 degrees and using frequent rest breaks.

If you have any questions get in touch with the HazardCo Team today

These days everything is digital. Your payroll is managed online, you keep your team organised via email, and you can even order lunch straight to your site with just a few taps. So why are you still getting bogged down by Health and Safety paperwork?

HazardCo helps reduce the H&S burden with smart online tools to help you cut back on paperwork. Plus, it’s a time saver with its straightforward templates and reports which are full of tips and suggestions to give you the confidence that you have all your bases covered.

You can create a Risk Assessment, Toolbox Meeting, Site Review, Incident Report, or Vehicle Checklist using the HazardCo App on your smartphone or tablet. The app has tools to guide you through each of these tasks, making them a breeze to complete anywhere, and at any time. No longer will H&S be a taxing task because HazardCo members can stay on top of their H&S whenever it works for them, whether that be on-site, while grabbing a morning coffee, or pretty much anywhere that works for them.

We’ve found that people who have embraced going digital as part of their H&S strategy have seen it remove roadblocks, distractions, and excuses – because when you have H&S in the palm of your hand, you can’t not do it. Plus it leads to a safer worksite when H&S is the focus of people’s thoughts and actions.

At HazardCo, we understand the importance of H&S for keeping your team engaged, on track, communicating, and most importantly, safe.

If you haven’t gone digital with your H&S there’s no better time than now. Builders and tradies can start their free seven day trial today and see the difference that HazardCo can make for your H&S plan.

You know that old saying… “no pain, no gain’”. Well this is not true! Just because you work in the construction industry doesn’t mean that you need to be affected by short or long term pain.

Aches and pains are some obvious symptoms of musculoskeletal disease (MSD), but have you thought about what impacts MSD are having on you outside of work in your personal life?

What if constantly performing the same repetitive movement all day is causing you acute pain that means you aren’t able to kick the football around with your kids after work, or play golf on the weekend with your mates? Do you really want your work to impact your personal life, or your workers lives when there are some simple steps that could prevent it from happening?

As a business owner have you thought about the hidden costs?

Data shows that strains and sprains often become more problematic later in a construction worker’s career, with the largest claims in the housing construction sector. Between 2015 and 2019, 57% of ACC claims were MSD injuries, with the average cost being $3700, and a total of 1.9 million compensation days paid out, costing a total of $325m!

There is a large range of costs that surface when someone has an injury on the job, especially when they can’t return to work the next day or sometimes weeks or months. This has a huge impact on deadlines, bottom line, skills on-site and team dynamics.

Risky work that can cause MSD’s can be as simple as overhead or floor level work, manual and hand intensive work.

Have you thought about other ways you could be working to alleviate the stress on your body? It could be as simple as:

It’s common practice when you work out, that you warm-up and cool down, so why is working any different?

Accepting the reality of MSDs helps us formulate an effective approach to combat MSDs in our

Industry. There are a lot of myths out there about MSD, such as its caused by poor manual handling techniques. The trouble with myths is they create unnecessary fear and hinder progress so they need to be challenged. Over time, new evidence emerges to help us understand the reality of the situation and

our understanding of MSDs has changed significantly over the years. For example Len Rings saying “Don’t use your back as a crane” is no longer repeated as we now know you need to move your spine through its whole range of motion regularly to keep it healthy and strong.

Check out CHASNZ top five MSD myths in construction.

Let’s do our bit and raise awareness on-site around MSD. Next week we will give you some exercises that you can do to avoid being affected by MSD and if you are hurt how physiotherapy can help you.

If you have any questions reach out the the HazardCo team

Mistakes or incidents can occur if machinery is not used correctly or by trained operators.

Training and supervision

Make sure your team has the right information, training, and instructions required for the task. Having the right people involved means workers will have the skills and experience needed to complete the job safely and the task hazards will be easily identified.

Workers should be adequately trained to operate machinery. To test this knowledge, workers should be monitored and assessed regularly against operating procedures.

Pre-start checks

Always check your equipment is fit for use at the beginning of each day.

A trained and competent machinery operator should be conducting a pre-start check before use. This gives you the certainty that your equipment is good to go for the day and won’t cause you any unexpected problems or delays. Things to check are:

Visual checks before turning the equipment on:

Stationary function test while equipment is on:

Moving function test:

We recommend using your manufacturer’s pre-operational check sheet and keeping these records with your equipment. Use of the HazardCo Heavy Machinery Prestart checklist will help you cover these specific checks.

Quick hitches, safety locks and exclusion zones

Quick hitches allow you to quickly and easily change buckets or attachments on your machinery. When using quick hitches and attachments you should always check the following:

Failing to check these could mean your bucket becomes detached or someone could get hit.

All quick hitches should clearly display the following information:

Safety locking pins need to meet the quick hitch manufacturer’s specifications and should be kept with the machinery or quick hitch device when not in use. Ensure that attachments are fitted with the correct pin centres and diameters.

Exclusion zones should be clearly marked out and all those working nearby should be informed. The hazards, risks and controls for machinery on-site should be covered in your job safety plan and shared with all on-site.

If you have any questions get in touch with the HazardCo Team today

Do you know what you need to do before you demolish or refurbish a property, building or structure? Find out what the asbestos regulations mean for you before doing any work.

Identifying Asbestos

Planning is key to identifying all potential hazards and the risks involved when doing any sort of demolition or refurbishment work. Asbestos can be found in buildings constructed or renovated before the year 2000 and as such it is more than likely to be present at your next job. You can find out more about where asbestos can be found in this WorkSafe resource.

Asbestos or asbestos containing material (ACM) must be identified and removed by a competent person before the demolition or refurbishment is started (unless demolition is required to gain access to the asbestos). Things to consider when planning your work:

If the competent person is unsure whether asbestos is present it must be assumed that it is and all steps taken to mitigate the asbestos risks. If asbestos is identified you must notify all parties involved such as the homeowner, landlord, occupant and/or the contractor in control of the site.

Asbestos Management Plan

Any works where asbestos has been identified will require an asbestos management plan. This outlines where any asbestos or ACM has been identified. Your plan must contain the following:

Other information may be included in the asbestos management plan, such as:

Emergency Planning

An emergency plan is required for demolition work where plant and structures contain asbestos. When developing the emergency procedure, you should consider:

The procedure should include:

The emergency procedure must be carried out if there is an emergency.

If the plant or structure is not structurally sound or is going to collapse, WorkSafe NZ should be notified as soon as possible.

Disposal of Asbestos

Before demolition starts, think of how you are going to dispose of the waste. Having a good waste containment and disposal process is just as important as having safe processes for working with asbestos.

Asbestos is considered special waste and special waste needs to be handled, buried, pre-treated or tested before it can be disposed of at the landfill. You need to make an application if you want to dispose of special waste.

Applications are often called special waste disposal declarations. Contact your local landfill to enquire about what they require before taking any material to them.

Not all landfills or transfer stations are authorised disposal sites, check with your local council to find out where your local authorised site is.

Double-bag all waste, all waste including single use masks and coveralls, cloths and plastic sheets should be double-bagged in heavy duty plastic bags. Twist the top of bags tightly, fold the necks over and seal with adhesive tape. Clearly mark the outer bag as asbestos waste.

Check with your receiving landfill for further details especially around handling details. There are often restrictions around how the material is offloaded.

If using skip bins or wheelie bins on site, be aware that many providers of these bins do not allow asbestos to be disposed of in them. Check your provider first for approval.

Document your disposal process in your Asbestos management plan and Asbestos Task Analysis (TA) considering the above.

As a HazardCo member you have access to a library of TA forms located in your Hub, which include demolition and the removal of non-friable asbestos for anything less than 10m2. Use of these resources will help you to identify the hazards and risks in your workplace and the recommended controls.

Our team of Health and Safety Advisors are here to help you with anything you are unsure of, give us a call on 0800 555 339, option 4.

Demolition is not just the knocking down of buildings or structures, it also includes smaller maintenance and renovation work such as the dismantling of parts of structures (e.g. one part of a steel-framed building) or the removal of walls.

When planning your works you need to first identify the hazards and manage the risks:

When demolition is involved there is always the potential for the collapse of the structures. Ensure structural / supporting elements are identified before demolition (you may need to seek structural engineers’ help identifying these, and in what order to take them down).

Make sure you have the following documents completed and available for your demolition work:

You can find these in your Templates Library in your Hub. You can login to your Hub here.

These should be tailored to the task at hand and regularly updated as changes occur.

If you have any questions reach out to the HazardCo team

With HazardCo, you don’t need to be on-site to know what’s happening. At the click of a button, the HazardCo Hub will show you who’s on-site, and it’s all available to you at any time, from anywhere.

It all works using a QR code:

Likewise, any H&S reports created on-site via the App are updated to the Hub straight away. This includes:

The QR code is the link between all on-site H&S activity and your project in the Hub. When you get everyone on-site using HazardCo’s digital system, you’ll always have a real-time view of the activity happening on your site, even when you can’t be there yourself.

With the HazardCo App, it’s as easy as picking up a smartphone to stay on top of on-site health and safety activity.

There are two key parts to the HazardCo system, the Hub and the App:

As the business owner, a lot of responsibility for H&S sits with you. However, with HazardCo’s digital system,you can add key team members to your Hub as App users, meaning any one of you can use the App to complete on-site H&S activity and those day-to-day tasks can be delegated or shared with others. All completed activity lands back in the Hub under your Project Overview, which you can review from anywhere and at any time.

The App features all of the key H&S activities you should be doing on-site, including Risk Assessment, Site Review, Toolbox Meeting, Vehicle Checklist, or Report an Incident. What’s more, if your subbies are also HazardCo members, they can use the App to scan onto your site and share any of their completed H&S activity directly to your Hub using the QuickShare feature on the App.

Learn more about all of the features on the HazardCo App and see just how straight forward it makes H&S for you and the team… this video overviews the HazardCo App, showing you all you need to know. Nothing beats the feeling of confidence you’ll get from being a HazardCo member.

Are you aware of when you need to notify WorkSafe NZ of your particular hazardous excavation works?

Conducting any of the following excavation works will mean you’ll need to complete this WorkSafe NZ online notification form:

It is expected that at least 24 hours notice is given prior to commencing such excavation works.

Notifying WorkSafe of your intended works allows them to gather statistics on the number of high-risk works going on around the country, and plan their use of resources to promote the prevention of harm.

Make sure you complete a Task Analysis for your high-risk works, you can access Task Analysis Templates from the Templates tab in your Hub. This will help you to identify the hazards, and the controls needed to minimise the risk to not only those involved in the works but all those working on the site.

If you have any questions or would like to discuss your particular hazardous works please feel free to call our Advisory team on 0800 555 339, extension 4.

Excavation work generally involves heavy machinery hazards and the need to manage vehicle and foot traffic on-site. Making sure you understand these hazards and how best to minimise these risks is key to ensuring the safety of those working in and around excavations.

Pre-start checks

Always check your equipment is fit for use at the beginning of each day.

A trained and competent machinery operator should be conducting a pre-start check before use. This gives you the certainty that your equipment is good to go for the day and won’t cause you any unexpected problems or delays. Things to check are:

Visual checks before turning the equipment on:

Stationary function test while equipment is on:

Moving function test:

We recommend using your manufacturer’s pre-operational check sheet and keeping these records with your equipment. Use of the HazardCo Heavy Machinery Prestart checklist will help you cover these specific checks.

Traffic Management

Managing excavations risks also means managing the risks of other contributing factors such as traffic. Keeping vehicles and pedestrians clear of heavy machinery and excavation works could mean you’re going to need a traffic management plan. When putting your traffic management plan in place you’ll need to consider the following:

Having a traffic management plan in place and discussing this at the time of site inductions means everyone entering the site is aware of the site rules, safe practices, and expectations before commencing work.

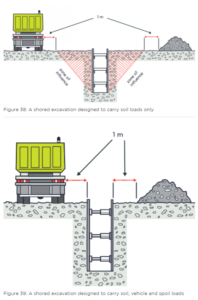

Zone of Influence – Know your limits.

Heavy machinery, as its name suggests, is heavy and carries a lot of weight. If being operated too close to excavations it can affect the stability of your excavations causing them to collapse. All heavy vehicles, material, and spoil should remain out of the zone of influence plus a metre unless specific designs are in place showing it can support such weight-bearing.

Tip-over

Uneven and unstable grounds can often lead to machinery tip-over. Tip-overs can cause serious injuries or worse, fatalities. Know the ground conditions you are working with and make sure you are following the outlined safety rules for your site. Ensure the following points are considered:

If you would like more information or to chat with one of our friendly Advisory team please give us a call on 0800 555 339, extension 4.

Sources:

Plant & Machinery Pre-start Checklist – Your Complete Guide

Managing work site traffic

Traffic Management Forms

Excavator tip-overs