When it comes to working safely at heights, make sure you’re eating a pie every Sunday. Wait…what?

Yep, you heard that right.

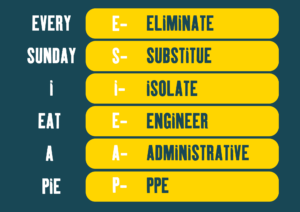

Remember the phrase: Every Sunday I Eat A Pie. It’s a handy way to remember the steps for staying safe: Eliminate, Substitute, Isolate, Engineer, Administrative, and PPE. These steps help you figure out what safety measures to use when you’re working at heights.

No matter the height you are working at, you have to make sure that you are controlling the risks, it doesn’t matter if that work is 40mm from the next surface or 40m.

Just like people argue about the best flavour of pie, there are different ways to working safely at heights, choosing the best methods such as the following examples of controls will be based on your specific situation, and the work being carried out. .

Eliminate: Not everything that needs doing has to be done “up there”. What tasks can be done on the ground before you have to do it at height? Every step achieved where you don’t have a risk of dropping objects is a reduction of other things to concentrate on when at height.

Substitute: What other methods can be used to get to the workspace? Instead of a ladder could you use a scaffold? MEWPs (like scissor lifts & boom lifts) can be really handy here, not only with safe access but also with making it easier on your body to get there and work all day.

Isolate: This means to physically prevent the contact between you and the risk (falling or even dropped objects etc) this can come in the form of guardrails, scaffolding, or nets to prevent things or people from falling to lower levels.

Engineer: This is a more permanent solution, think of your handrails on staircases or cleverly built seats with high backs around the edges of a raised deck. It’s built for purpose and will continue to deliver that outcome without you having to interact with it (passive protection) this is often referred to as safety in design.

Administrative: This is simply making people aware. Think about hazard boards, signs, warnings, toolbox talks or paperwork to communicate what you will be doing, how, and who is doing it when.

PPE: This is the likes of harnesses to prevent you getting to a place you can even fall if possible, and if you do fall then to lessen the severity of the injuries you would receive from a fall if set up correctly, a hard hat to protect your head from small items falling like screws and small items etc.

It’s important you and your team are actively involved in ensuring any work carried out at heights, is done in the safest way possible. Empower your team to speak up, highlight unsafe working situations or practices, and swiftly act to handle them.

We recommend doing a Task Analysis to put a plan in place to manage the risks involved with working at height. This will help you decide whether it’s possible to eliminate the risk of falling from height or what the most effective control/s are to minimise the risk.

So from the above, what’s your favourite flavour combinations? Which ones will satisfy your cravings to keep the team safe today?

If you’ve got a question about working at height or any other health and safety matter, the HazardCo Advisory Team is here to help. Give them a call on 0800 555 339

Over the last 18 months, consents for multi-unit dwellings have grown to the point where there are more multi-unit consents each month than for standalone houses. Coupled with the current economic climate and the security that comes from Council, Kainga Ora or Government work means we are seeing more and more of our residential builders starting to work beyond the more traditional single dwelling build.

There are three different types of residential housing – low density, medium density, and high density.

With increasing pressure on New Zealand’s building stock, medium density housing is considered an attractive option to meet the changing housing needs. Demand for more compact homes is increasing, particularly in areas with rapid population growth (BRANZ, 2023). Multi- dwelling consents made up 48% of all consents in 2021 and were forecasted to continue to increase (Stats NZ, 2021).

The key difference between low and multi dwelling housing is the level of complexity required to manage the build and the likelihood of additional layers of responsibility e.g. directors and development owners as PCBU’s above the building contractor.

This complexity of communication around safety means that the builds are often not solely run by a Group Home Builder or single builder and their subbies. Instead, for example, they can be run by project management companies, involving large stages of the build process that is then run and managed by specialists. This adds additional complexities compared to low density housing.

There are often complex stages of these builds, which are generally run by specialised subbies e.g. planning (engineers, architects, quantity surveyors), and build stages (civil works, construction management, carpentry/joiners, concreting) etc.

Because multi-dwelling housing creates more risk on-site due to the increased amount of subbies, machinery, equipment, and high-risk work taking place, It’s important that you have the right H&S tools in place for your contractors and a safe system of work e.g Site Specific Safety Plan (SSSP) for all medium density builds.

A SSSP for a multi-dwelling build will outline how all involved parties will manage health and safety on-site. This includes a detailed agreement between parties on how they will manage subbies, their expectations, roles, and responsibilities to ensure that all relevant site safety information is available.

The SSSP is intended to be a detailed agreement and communication tool. Due to the potential complexity of multi-dwelling builds, we always recommend a more detailed and customised SSSP.

This list is not exhaustive but all of these complexities are often above and beyond a low density build and need planning, controlling, and communicating to ensure the health and safety of workers and others are managed well.

Project Pro and the HazardCo system are suitable and capable of meeting the H&S requirements of multi-dwelling builds, so you can feel confident that HazardCo can support you as your business grows.

If you are a builder starting to diversify, now’s the right time to review your Health and Safety activity.

That’s where HazardCo comes in. If you’re building 3 or more dwellings within a fenced-off section, you will need HazardCo’s Project Pro. This is a customised project, specifically for your build that gives you everything you need for your team and all the subcontractors you will have coming onto the site.

Here are some key components of Project Pro that will help you cover all your bases.

If you have a new multi-dwelling residential project kicking off, give us a call on 0800 555 339 or email info@hazardco.com to discuss your requirements and what you need to be thinking about from a H&S perspective and the added complexities that come with it.

For building companies, scalability isn’t just a buzzword – it’s a necessity. Paul Dugdale of ARCA and Dale Spencer of Southern Ocean Building and Consulting, are shedding light on the importance of systems and technology when it comes to running an efficient, successful building company. Let’s dig into some key lessons from these experts.

Getting the right people on board and equipping them with the right tools and systems is the first step in scaling your business. To do this, identify bottlenecks in your existing processes and work out how to relieve these through either automation, delegation, or elimination. Being proactive and identifying what the critical points are in your business and making sure these run smoothly is a great way to make your business more efficient.

Knowing exactly where you are and if you are on track (or not) with your budgets is key to making sure your business succeeds. Being able to forecast to identify any problems, allows you to make changes to manage these. The best way to do this is to use integrated software that gives you oversight across your business and can also make financial forecasting more efficient which saves you time and frees you up to work on other parts of your business.

At the heart of scalability lies the ability to use software and systems to improve efficiency. The key is to use simple systems that offer both high-level overviews and can also easily drill down into the details, empowering the right people to make informed decisions quickly and easily.

Running a business is hard! And even our experts admit that there’s always something that pops up to keep you on your toes. Having the confidence to know that whatever tomorrow brings because you have created strong and resilient systems in your business you will be able to deal with those problems, gain knowledge from them and create a strategy to fix them, will mean that you will continue to build a successful business.

Remember you can’t do it all so finding the right way to do it is the key to success.

Watch the full video to discover the systems and integrations that Paul and Dale have used to successfully scale and take their business to the next level.

Running a safe site isn’t just about wearing hard hats and harnesses; it’s about effective communication and staying aware of what’s going on on-site. One of the most powerful tools is the humble toolbox meetings. These gatherings are the backbone of ensuring everyone on site is up to speed with hazards and safe working practices.

Download the Simple Guide to toolbox meetings to get tonnes of ideas for toolbox meeting topics.

Toolbox meetings are a forum to highlight safety expectations and encourage participation from everyone on site. They don’t need to be lengthy; a quick stand-up meeting will do – maybe even with a side of chocky biscuits to sweeten the deal! We recommend holding these meetings weekly, or at least twice a month, to keep safety at the front of everyone’s minds.

Some building companies take it a step further by incorporating toolbox meetings into their daily routine. Starting each day with a brief safety discussion helps to make safety a daily habit, rather than an afterthought.

The success of a toolbox meeting hinges on a few key factors:

Here are some prompts to kickstart discussions in your toolbox talks:

Toolbox meetings help with communication, collaboration, and continual improvement. Remember, safety is a team effort, and toolbox meetings are where that effort begins.

The HazardCo App includes all the on-site safety reports you need, such as a handy tool to record toolbox meetings.

Task Analysis (TA) is an important tool in your health & safety toolbox. It helps you to break down complex tasks into smaller, manageable steps while ensuring safety and efficiency. In this guide, we’ll explore what TA is, when and why it’s used, how to complete one effectively, and the benefits of using digital platforms for streamlined TA management.

A Task Analysis (TA), also known as a JSA or SWMS, breaks complex tasks into a sequence of smaller steps and actions. They are used as a planning tool to make sure all risks and controls are identified and appropriately managed for your job. A Task Analysis should describe how you plan to complete the job safely and proves that you are managing the risks effectively.

A Task Analysis should be used to identify and assess the hazards before each high-risk job to reduce the risk as much as possible. For repetitive tasks, you don’t need to create a new Task Analysis each time, as long as the prepared Task Analysis is relevant to the work being completed and understood by all persons involved.

Completing a Task Analysis helps to make sure all risks and controls are identified in each work step to improve safety and performance. It also ensures that the correct tools, people, and processes are identified before you start the job which minimises the risk of injury, provides a clear understanding to workers, and increases productivity.

To complete a Task Analysis, carry out the following steps:

Remember the Control hierarchy is:

It’s a simple and easy to repeat approach, where you can:

Manage subbies? If you are on our Premium, Complete or Project plus tiers you can even digitally collect TA’s from subcontractors without the fuss!

The TA template on the App guides you through a step-by-step creation process. It gives you the confidence that the potential hazards have been thought through, and that the appropriate controls have been put in place to eliminate risk where possible or minimised.

You can create a Task Analysis template in preparation for your upcoming works. This template can be updated with the job specific details. Creating a Task Analysis before arriving at the site and customising it for each job will set you up to quickly communicate with the team, manage the risks and get on the tools. When making your templates avoid ticking controls you won’t implement. The suggested controls list is not exhaustive, so make sure to include any additional controls you plan to use.

Once you have selected your hazards, the controls you will implement, and noted the steps you will follow to complete the task, hit SAVE. A HazardCo Task Analysis is then created, emailed to you, and saved securely in your App and Hub so you can easily share it with the main contractor and anyone else you may need to coordinate with.

If you need a hand getting started or would like more information on the HazardCo app read this blog or get in touch with the friendly HazardCo team today on 0800 555 339.

It’s never good to find out the hard way that there was a gas, power, water or communications line buried right where you needed to put something on your site! Safe excavation practices help you to get through the work without injury and avoid hitting critical services.

Digging blind is not the best way forward for your schedule or your safety, so we have put together some key notes for you to bear in mind when excavating to help save you some costs, time and help you to avoid tragedy.

Excavation work is referred to as any work involving the removal of soil or rock from a site to form an open face, hole or cavity, using tools, machinery or explosives. This includes open excavations, potholing, pit excavations, trenches, retaining walls and shafts and drives.

Employers have a legal duty of care to take reasonable actions to protect both the people and the services which may be affected by their work. Getting and using the appropriate information on the services is an important part of ensuring safe excavation on your site. There is a large range of options this can cover, so we will cover the basics in this article.

If you have more complex excavations and want advice then get in contact with us.

Remember any ground disturbance regardless of depth can damage infrastructure networks like gas, water, electricity so you need to get the right information to keep you & the utilities safe.

First, you need to get information on what the assets in the area may be. You can often get this information from BeforeUdig. This online system is the easiest way to request known plans from the asset owners. It is important to know that not all Asset Owners are members of BeforeUdig, so it cannot show you everything that is in the area of your excavation. You may need to contact any other asset owners directly to get hold of plans, drawings and information regarding their assets known positions prior to starting your work.

Wait to receive all information on the assets before commencing work, and only refer to plans that are current.

Once you have information on the assets, make sure the plans are with the workers on-site and that they have appropriate health and safety information and instruction. You should also isolate work around the underground assets from the public.

Pay attention to the clues around your site such as marker posts, inspection points and metres. Never assume pipes and cables run underground in a straight line or are at their correctly specified depth, and always assume all lines are live, even if they look as though they are abandoned or decommissioned.

Remember all digging activities can damage underground infrastructure. You should conduct a risk assessment for the task so that you can identify the hazards to focus on, and put in place suitable controls. Workers involved in the excavation need to be trained and competent to do their part of the work e.g the Excavator operator is appropriately licensed.

To minimise the risk of damage and potential loss of life, it’s best practice to follow the 5 P’s for safe excavation:

Remember to stay vigilant and watch for changes in the ground/soil as you dig.

If you’ve got a question about safe excavation or any other health and safety matter, the HazardCo Advisory Team is here to help. Give them a call on 0800 555 339.

The BeforeUDig NZ website has a tonne of resources available. Worksafe NZ also has a Best practice guide.

In the world of construction, its common for duties and health and safety responsibilities to overlap. This can be managed simply, you just need to be organised, proactive and ready to collaborate with everyone on site.

Business owners are required to manage the risk to health and safety of workers, other contractors or any visitors who might be affected by worksite operations.

On-site this means there can be a lot of overlapping duties, so the main contractor is responsible for coordinating with other businesses/trades/subcontractors so they can all meet their combined responsibilities. See the image below:

Duties can overlap in a shared workplace where more than one business and its workers influence the work on-site. There can be overlapping duties when business and workers do not share a workspace, see image below.

An example of overlapping duties when not sharing a workspace is in a contracting chain, where contractors and subcontractors provide services to a main contractor (or client) for a project but don’t necessarily share the same worksite.

Consultation. Cooperation. Coordination. The 3 C’s are here to make overlapping duties that little bit easier. Especially for businesses. Let’s break down how and why:

The duty to consult means getting together, planning ahead and identifying any underlying health and safety issues, risks and methods of controlling these risks around the work being carried out. Consultation could require discussions around:

This simply means working together and sharing information. Putting in place a system for managing and controlling risk in accordance with any ground rules laid down during the consultation process.

Making sure everything is working together as it should. Coordinating on what systems or processes will be implemented and how to control the risks.

It is important to note this isn’t about one business pushing all the duties on another. It’s about everyone involved working together to avoid duplication, and effectively manage health and safety risks.

What may seem like a hassle at first, is actually a huge benefit to on-site operations. For example certain contractors on-site will be better placed to identify risks that other contractors might not be aware of. In other circumstances, cooperation could save on cost with businesses avoiding duplication.

Keeping people safe should always be the top priority on any construction site. What’s more, health and safety law actually requires this to be the case. Aligning yourself with other parties, and knowing what safety systems are in place is vital and could save lives.

Seeking advice early on how you can help develop efficient strategies, and reading this article is the first step! To know more about safety on-site you can contact one of the HazardCo team today.

We’ve released some handy new tools to make managing your contractors and their overlapping duties really simple. Project Plus unlocks the HazardCo app for everyone to use on site , so your contractors can create and submit site reviews, toolbox talks and more. And the new pre-qualification tools included in the Complete plan will help with the heavy lifting when it comes to checking your contractors health and safety is up to scratch.

If you are a contractor and you have questions on how to best work with other businesses or the process you should follow, have a look at our working with other businesses blog.

Having workers engaged in work health and safety will help your business be a healthier and safer place for everyone, and performance and productivity increases. It’s a win-win!

Under the Health & Safety at work Act (HSWA), businesses have a duty to engage with workers and enable them to participate in improving health and safety. The business must:

Remember that your subbies are also considered your workers when they are working for you.

Together with your workers, you can determine the best way to meet these requirements. What is reasonable and practicable will depend on your workers’ views and needs, the size of your business, and the nature of its risks.

Businesses must:

When is engagement required?

You will need to engage and consult with workers who are directly affected by a matter relating to health and safety. This includes when:

It’s important to have meaningful and effective health and safety talks. It’s good for people and for business. This doesn’t mean hour-long talks or lots of documentation, it’s simply about approaching H&S with the right attitude and aiming to get everyone involved.

HazardCo makes it even simpler to do this with our ‘Toolbox Meeting’ feature on our HazardCo App – handy for making sure everyone on-site is keeping on top of what’s going on.

You can also check out the health and safety at work strategy for worker engagement, participation, and representation here.

If you need a hand getting started or would like more information, get in touch with the friendly HazardCo team today.

Any work undertaken near live overhead power lines carries the risk of electric shock. Touching a live overhead line with any part of the body, tools or any other equipment can cause serious injury and even fatality.

Make sure that you and your team are aware of the following steps that can be taken to manage the risk of an electric shock.

Forward planning is essential. Before work starts, the person in control should:

Disconnecting the electric supply for work between 0.5 metres and 4 metres

The safest option to eliminate the risk of electric shock is to temporarily disconnect a property’s electricity supply from the electricity distribution lines so that the overhead line to the property is no longer live.

Keep people informed so they can plan ahead

Find out who needs to know that the electricity supply will be temporarily disconnected. Such as:

Anyone who could be affected by the disconnection of the electricity supply should be told:

If work needs to take place near an overhead electric line then the worker’s body, their tools, and their equipment must be kept a safe distance away from the overhead line, else the electrical supply must be disconnected by the approved electrical retailer. This safe distance is known as the minimum approach distance, or MAD.

For more information around consent visit Section 10 of the WorkSafe Working near low voltage overhead electric lines guide.

Keeping you and your team safe at work is a priority, so make sure you are aware of the requirements of working near power lines. The HazardCo App Site Review resource has a list of electrical controls that should be in place to mitigate the risk of electrical hazards. If in doubt, you can give our team of Health and Safety Advisors a call on 0800 555 339.

Worksites tend to be filled with constant noise from tools and machinery. Work-related hearing loss is a real threat for many who spend the majority of their working lives on-site. While noise often means things are getting done, there is a downside to it. Hazardous noise can affect a worker’s physical and mental wellbeing including hearing loss, stress, and lower productivity. So to help you protect your hearing, here are a few helpful tips to manage noise.

Understanding what makes noise on-site, how it impacts people and different areas on site is critical. Ask yourself and your workers:

Once you understand the answers to the above, you can start putting plans and checks in place to monitor noise on-site.

Be sure to review the plan throughout the project, as different stages will create varying levels of noise.

The easiest way to decrease the effect of excessive noise on your site is to eliminate the source of noise completely. But, chances are this isn’t possible on a busy site.

The next best thing is to reduce noise.

A couple of easy ways to do this include:

Isolation involves creating a dedicated space for ‘noisy work’. This could be an enclosed room or area of site where all noisy work and machinery is used. This helps manage the noise by blocking the path of noise and reducing the levels that reach your team.

Having a good understanding of how machinery and tools operate can help modify processes to reduce noise at the source. Engineering controls can include choosing attachments or parts that are noise reducing, or changing the way machinery and tools are used.

Perfect for when you are running a large generator or a dedicated workspace, acoustic enclosures help to trap the noise within its barriers.

Setting up an acoustic enclosure that has 2 or 3 barriers/ walls can reduce noise.

What makes a quality acoustic enclosure:

With noise comes vibrations. These vibrations can be just as harmful as the noise itself.

Here are a few strategies to help decrease vibrations when using machines or power tools:

It’s not possible to escape noise on-site, however we can manage noise and put steps in place to help reduce the effect that it has on us while we’re working.

If you have any questions don’t forget to reach out to the team!